SANDWICH

We produce about 8000 square metres of insulated panels per year. Our Service Centre, with its wide range of technologically up-to-date equipment and machines, enables us to carry out the panel production in-house. Made of polyurethane foam coated with stainless steel on the inside and galvanised steel on the outside

Our panels are adaptable to the customer’s needs thanks to the possibility of changing finishes and materials, as well as sizes and shapes. In addition, they are custom-designed in the factory to be fitted on board ship, creating cells with the exact footprint and space required.

INNOVATION

PRIMARY

PROPERTIES

The cell floor finishes and the internal sandwich composition are the result of several innovations in order to:

Guarantee different anti-slip grades from r9 to r12

Realising lashing systems embedded in the bottom of the panel

Obtaining different surface flow rates

Having low thermal conductivity values, even on the floor

PROPERTIES:

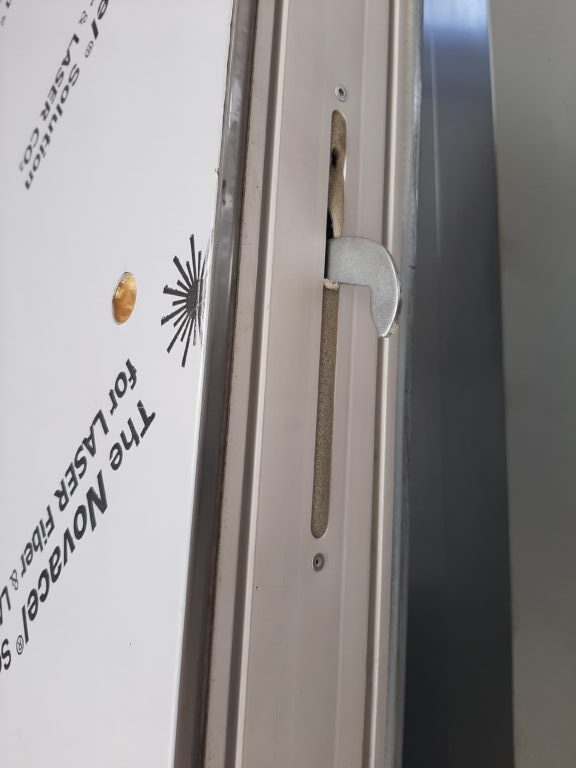

Rooms feature a new ceiling panel with a fastening system that allows for improved appearance aesthetics, thermal improvement, mechanical improvement and assembly improvement.

The Cam Lock system reinforces the tensile strength and corrosion resistance. The PIR foam coating guarantees fire resistance as well as improved thermal insulation performance. Finally, the PVC coupling profile reduces the production of ice and/or frost from damp Air.